- Home

- Knowledge Center

- UV Printing Benefits for the Environment: How UV Curing Helps

UV Printing Benefits for the Environment: How UV Curing Helps

Contents

As global pressure increases to reduce industrial emissions and waste, the printing industry is undergoing a critical transformation. Traditional printing methods are no longer sustainable, either environmentally or economically. In response, UV printing, powered by UV curing technology, has emerged as a faster, cleaner, and more energy-efficient alternative.

In this article, we’ll explore why UV printing benefits today’s manufacturers not only as an eco-friendly option but also as a strategic move for sustainable growth and regulatory readiness.

What Is UV Printing?

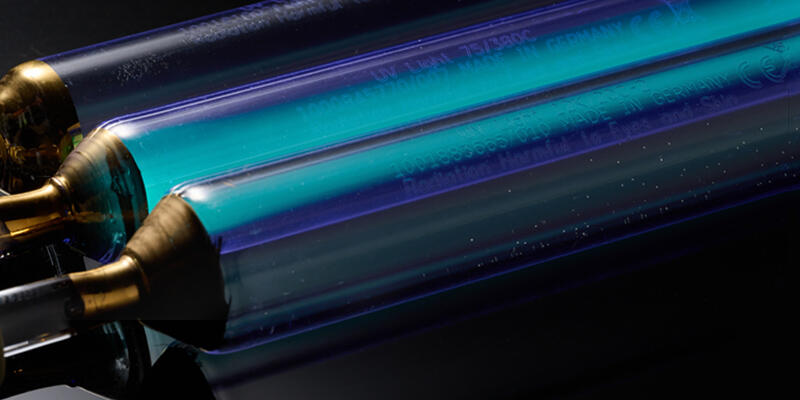

UV printing is a modern printing method that uses ultraviolet (UV) light to instantly dry the ink. As the ink is applied to the surface, it passes under UV lamps that trigger a rapid photochemical reaction, transforming the liquid ink into a solid within seconds.

Unlike traditional printing methods that rely on heat or evaporation to dry the ink, UV printing requires no drying time and releases no solvents. This results in a faster, cleaner, and more efficient process, along with consistent, high-quality results.

It is particularly effective on non-absorbent surfaces such as plastic, glass, or metal, where conventional inks would take much longer to dry. Today, UV printing is widely adopted in industries such as packaging, signage, and product decoration, all of which demand speed, durability, and high-quality output.

3 Key Advantages of UV Printing

UV printing offers distinct advantages over traditional methods in several key areas:

Outstanding Print Quality

Since the ink cures directly on the surface of the material rather than being absorbed, it forms a solid, even layer. This results in richer, more vibrant colors and sharper details, ideal for high-resolution graphics and brand-sensitive applications. The cured ink is also highly durable, offering excellent resistance to scratches, moisture, and fading.Compatibility with Various Materials

UV printing works on a wide range of substrates, including plastic, glass, metal, wood, acrylic, and both coated and uncoated paper. This versatility allows businesses to apply the technology across a variety of use cases, from packaging and signage to promotional products and industrial parts, without compromising quality or performance.Eco-friendly

UV printing supports more sustainable production in several ways. It emits fewer volatile organic compounds (VOCs), operates with greater energy efficiency, and produces long-lasting results, reducing the need for reprints. These qualities help companies meet their ESG goals while maintaining high production standards. We’ll explore this further in the next section.

How UV Printing Benefits the Environment

UV printing, powered by advanced UV curing technology, offers numerous environmental benefits that distinguish it from conventional printing methods.

Low VOC Emissions

Traditional curing methods often rely on solvent-based inks, which release VOCs into the air during the drying process. These emissions contribute to air pollution, degrade working conditions, and pose health risks to operators.

In contrast, UV printing eliminates the need for solvents. The instant curing process uses UV light to solidify the ink without solvent evaporation, resulting in negligible VOC emissions. This contributes to a safer, cleaner production environment and supports compliance with increasingly strict air quality and emissions regulations, particularly in environmentally conscious markets such as the EU and North America.Low Power Consumption

A common misconception is that UV curing may be energy-intensive due to the use of high-intensity light. In reality, UV curing systems are designed for energy efficiency. Unlike conventional thermal drying, which requires prolonged heat exposure, UV curing completes the process in seconds. This faster curing speed reduces drying times, shortens production cycles, and leads to significantly lower overall energy consumption. The efficiency not only reduces carbon emissions but also helps businesses cut energy costs and extend equipment life through reduced thermal stress, making it both environmentally and economically efficient.Reduced Material Waste

Instant ink curing plays a key role in minimizing waste. Since the ink cures instantly upon contact, the risk of smudging, misalignment, or ink bleeding is virtually eliminated. This leads to a dramatic decrease in print defects and rejected materials. UV printing also offers superior color accuracy and consistency, reducing the need for test prints, touch-ups, or reprints. By producing high-quality output with minimal trial and error, UV printing helps conserve substrates, ink, and energy, lowering the environmental impact of each production run.Long-Lasting Printing Quality

From a lifecycle perspective, UV printing offers exceptional durability that translates directly into environmental benefits. UV-cured prints form a resilient surface layer that withstands abrasion, moisture, and UV exposure. Unlike traditional prints that may fade or degrade over time, UV prints retain their quality and vibrancy for much longer. This durability reduces the need for frequent reprinting or product replacement, conserving both materials and operational resources over the long term. In industries like packaging, signage, and outdoor advertising, this extended lifespan can make a significant difference in reducing environmental waste.Compatible with Eco-friendly Materials

UV-curable inks are typically formulated without solvents and often free of heavy metals, making them a safer and more sustainable choice. Since they cure primarily through internal photopolymerization with minimal chemical interaction with the substrate, they are less likely to affect the recyclability or compostability of eco-friendly materials.

This makes UV printing particularly well-suited for use on recycled plastics, biodegradable boards, FSC-certified paper, and other sustainable substrates. Because the ink remains on the surface instead of soaking in, it helps preserve the core properties of the base material, ensuring that printed products can still be recycled or composted without contamination. This compatibility aligns with circular economy principles and enables brands to meet their sustainability goals without compromising on design or performance.

UV Curing: A Smart Investment for Long-Term Sustainability

The many advantages of UV printing—from superior image quality to lower emissions and faster turnaround—are made possible by one essential technology: UV curing. This advanced curing process is the driving force behind UV printing’s performance and environmental benefits, enabling more sustainable and efficient workflows.

As pressure mounts to reduce VOC emissions and energy consumption, UV curing emerges as a practical, future-ready solution. It not only ensures compliance with current environmental standards but also positions businesses to adapt to evolving regulations. Beyond regulatory alignment, UV curing streamlines production and strengthens brand credibility. In an era where sustainability is a business imperative, adopting UV curing technology is more than a technical shift—it’s a strategic step toward long-term efficiency, resilience, and market leadership.

Looking for the right UV curing solution? UV Light is a trusted partner known for its innovative UV curing systems and outstanding customer support. We collaborate with print businesses worldwide to unlock new levels of efficiency and sustainability. Contact us today to learn how our solutions can help you meet your sustainability and production efficiency goals.

About the Author : Follow us on LinkedIn.