- Home

- Knowledge Center

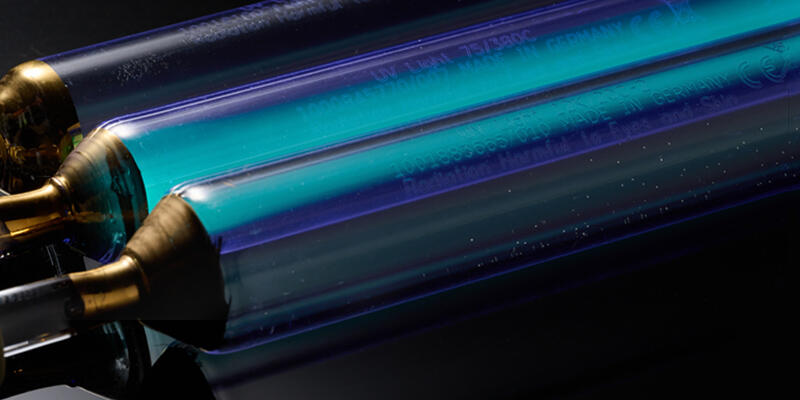

- LED UV Technology and Industrial Applications - UV Light

LED UV Technology and Industrial Applications - UV Light

In response to the pressures of energy shortages and environmental concerns in the mid-1960s, UV technology began to develop and promote. Due to its convenience and cost-effectiveness, UV processes have been widely used in industries such as printing, electronics, woodworking, furniture, automotive, and other industrial applications. In recent years, the global trend of energy efficiency, carbon reduction, and environmental protection has led to the emergence and continuous development of LED UV technology. The following is a brief introduction to the advantages of LED UV and its applications in printing:

◎ Eco-friendly, aligning with environmental standards

-LED UV generates no ozone or mercury.

◎ High intensity effectively improves production speed

-By using high-power LED chips and unique optical designs, LED UV achieves precise, high-intensity irradiation. It outperforms traditional mercury lamp methods with an irradiation intensity surpassing 20W/cm2 and optimal output uniformity, thanks to modern optical technologies and manufacturing processes.

◎LED UV is more than 80% energy-efficient

-Unlike mercury lamps, LED UV curing systems are highly efficient, consuming power only during use. With instant on-off capabilities, they significantly reduce standby power consumption, which is nearly zero.

◎ The lifespan of LED UV is more than 10 times that of traditional UV lamps

◎ Intelligentization and Data Feedback Mechanism

–Integration of mobile apps or cloud systems for real-time monitoring and sensing, including power, operating hours, and error detection.

LED UV curing technology is the ideal choice for UV ink curing in various applications, such as offset printing, labels, packaging, bottle printing, 3D printing, barcode and labeling, posters and signs, and others.

Considerations for LED UV application and implementation LED UV technology is currently mainly used in the printing industry with UVA (Ultraviolet A) and often designed with a single wavelength. Therefore, it is important to understand the wavelength range to which the LED UV can react when introducing it, in order to maximize its effectiveness.

Article source/ UV Light Enterprise Co., Ltd.

About the Author : Follow us on LinkedIn.