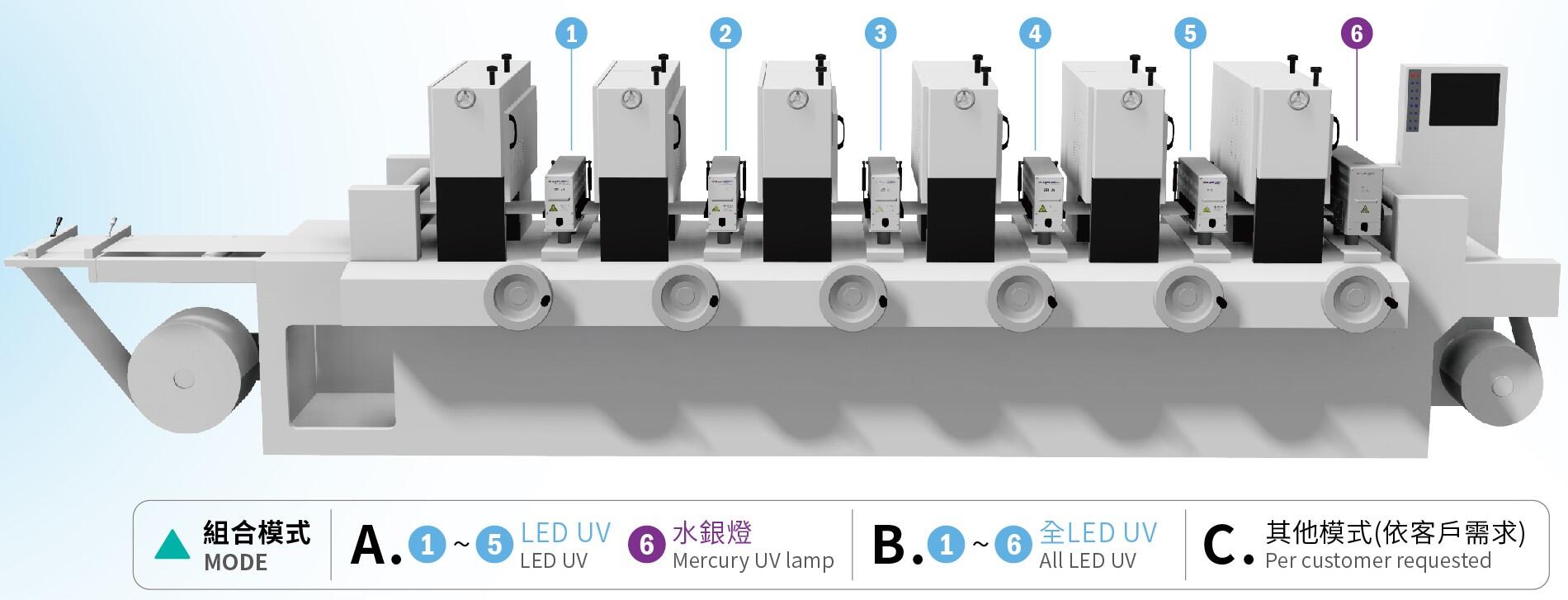

UV Curing Systems

A UV curing system, short for ultraviolet curing system, is a technology used for quickly drying or curing inks, coatings, adhesives, and other materials by using ultraviolet (UV) light. This system involves the use of UV light to initiate a chemical reaction in the material, causing it to harden or dry almost instantly.

The UV curing systems manufactured by UV Light are widely used in consumer goods, including printed packaging, glossing on packaging boxes, self-adhesive labels, electronics, wood products, spray coatings, and more. These systems offer enhanced gloss, abrasion resistance, solvent resistance, and improvements in printing efficiency and quality. Additionally, real time monitoring ensures that the curing process is consistently optimized, providing precise control and data analysis for enhanced product quality.

Features

- High power output up to 600W/INCH.

- Curing width available from 150MM to 1500MM.

- Indirect reflection lowers the temperature of the material more than 55%.

- UV power auto adjustment to suit the speed of the web press.

- Available for lower temperature design of air/water curing type.

- Designed for curing heat-sensitive optical films.

As one of the leading UV manufacturers in Asia, UV Light also provides real time monitoring solutions for UV curing.

Optional:

- Built-in efficient German-made dichroic reflectors.

- UV Energy Real-time Analyzer System.

- Real-time UV energy monitoring, and data management.

- Fine tuning for different quality segments.

- Curing quality data could be accessed easily.

- Providing curing data for in-depth analysis of product quality.

UV Light has been devoted to designing and manufacturing UV systems for different fields since 1983. We are ISO 9001:2015 certified. UV Light is your trusted partner in UV curing technology, quality, and excellence. For further details and inquiries, please do not hesitate to contact us.