- Home

- Knowledge Center

- LED UV Curing vs. Traditional Mercury Lamps

LED UV Curing vs. Traditional Mercury Lamps

Contents

Think about the products you use every day – a shampoo bottle in the shower, a yogurt cup from the fridge, or a package you just opened. The printed labels, flexible films, and coated surfaces on these items were likely made using UV curing technology, which gives them the sharp details, vibrant colors, and durable finishes we often take for granted.

Behind every successful UV curing process is the right kind of light. In the sections that follow, we’ll look at two main UV lamp types – traditional mercury and modern LED – and how your choice can affect curing speed, energy use, and final product quality.

Why Choosing the Right UV Lamp Matters

Choosing the right UV lamp matters because not all UV lights work the same way – and if the lamp’s output doesn’t match the material’s chemistry, curing simply won’t happen as intended.

UV curing is a chemical process that depends on photoinitiators – light-senstive ingredients in inks, adhesives, or coatings that respond to specific UV wavelengths. If the lamp emits the wrong wavelengths, these photoinitiators won’t activate, and the surface may remain tacky, cure unevenly, or fail entirely.

That’s why lamp selection isn’t just a technical detail – it affects everything from curing speed and surface quality to energy use and product durability.

So, what makes one UV lamp more effective than another? It comes down to three key technical factors that directly affect how well your material cures:

Wavelength Compatibility with Materials

If the lamp’s wavelength doesn’t match the material’s photoinitiators, curing won’t fully occur—leading to tacky surfaces, weak adhesion, or poor durability. For example, inks and coatings used in packaging or flexible films often respond best to longer UVA/UVB wavelengths (320–400 nm), while high-strength adhesives for glass or metal may require shorter UVC wavelengths (200–280 nm).Energy Distribution

Whether energy is concentrated or dispersed affects how evenly a surface cures. Uneven curing can weaken adhesion and reduce the final product’s strength.Thermal Impact

Unlike traditional drying, UV curing doesn’t rely on heat—but UV lamps can still generate heat as a byproduct. Excess heat may warp or damage heat-sensitive substrates during curing.

In short, effective UV curing depends on the right match between lamp performance and material requirements—especially when it comes to wavelength, energy focus, and heat output. With these factors in mind, let’s take a closer look at how the two main types of UV lamps—mercury and LED—compare in real-world manufacturing.

Types of UV Curing Lamps: Mercury UV vs. LED UV

In modern manufacturing, two main types of UV lamps are used for curing: mercury vapor lamps and LED UV lamps. While both can be effective, they work in very different ways and suit different production needs.

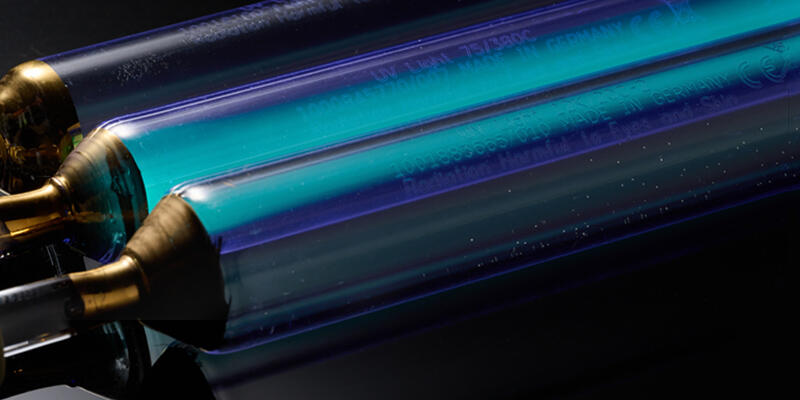

Mercury Vapor UV Lamps

Mercury vapor lamps are one of the earliest technologies used for UV curing. Inside the lamp, mercury is heated until it turns into vapor, which then emits ultraviolet light when energized. This process produces a wide range of UV wavelengths, making the lamps versatile – but also more complex in how they behave and perform.Broad Wavelength Output

Emits UVC, UVB, and UVA light (approximately 200–450 nm), including some visible blue-green light. Only part of this spectrum contributes to curing, which reduces energy efficiency.Metal Additives

Elements like iron (Fe), gallium (Ga), or indium (In) are often added to boost output at specific wavelengths.Ozone Emission

UVC light below 242 nm can react with air to generate ozone—a toxic gas—which requires ventilation for safe operation.High Heat Output

Mercury lamps release significant heat, which can damage sensitive materials like plastic films or electronics.Short Lifespan

Typically lasts 500–2,000 hours, leading to frequent replacements and higher maintenance costs.

LED UV Lamps

LED UV lamps are a newer technology that generates ultraviolet light using semiconductors – solid materials that release energy as light when electricity flows through them. These lamps produce specific UV wavelengths without using heat or gas, which means less energy is wasted and the curing process is easier to control.Narrow Wavelength Output

Typically emits UVA light at 365, 385, 395, or 405 nm. This focused range reduces energy waste and ensures consistent curing.No Metal Additives Needed

The output wavelength is determined by the semiconductor material, so no additional elements are required.No Ozone Emission

LEDs do not emit UVC light below 242 nm, which is the range that reacts with air to produce ozone. Since no ozone is generated, there’s no need for ventilation.Low Heat Output

LEDs generate much less heat, making them ideal for temperature-sensitive materials.Long Lifespan

Often lasts 20,000 hours or more, reducing replacement frequency and maintenance costs.Instant on/off

LEDs light up immediately and don’t require warm-up or cool-down time, improving production control.

Why Are LED UV Lights A Better Choice for Curing?

LED UV lights are often preferred for their efficiency, consistency, and low heat output. They cure materials more precisely, require less maintenance, and avoid issues like ozone generation. While mercury lamps still have their place, LEDs are better suited to most modern production environments.

The table below highlights the key differences between the two:

| LED UV Lamp | Mercury Lamp | |

|---|---|---|

| Wavelength Output | Narrow, targeted (365–405 nm) | Broad spectrum (UVC–UVA, ~200–450 nm) |

| Energy Efficiency | High | Low |

| Ozone Emission | None | Yes (requires ventilation) |

| Heat Output | Low | High |

| Lifespan | 20,000+ hours | 500–2,000 hours |

| On/Off Time | Instant | Requires warm-up |

| Equipment Size | Compact | Larger, bulky |

Conclusion

As UV curing continues to advance across industries—from electronics and packaging to precision optics and 3D printing—selecting the right UV light source is more important than ever. While mercury vapor lamps still have value in certain specialized applications, LED UV systems offer greater efficiency, lower maintenance, and a more sustainable path forward for most modern production needs.

Ultimately, choosing the right wavelength isn’t just a technical detail—it’s what ensures faster curing, better adhesion, and more reliable results. Whether you're printing labels, coating components, or bonding materials, aligning the UV light with your material's photoinitiator is key to curing success.

Looking to upgrade your system? UV Light offers high-performance LED UV solutions, with mercury options available when needed—customized to match your production goals. Get in touch to find the setup that’s right for you.

About the Author : Follow us on LinkedIn.