- Home

- Knowledge Center

- How UV Curing Elevates the Flexographic Printing Process

How UV Curing Elevates the Flexographic Printing Process

Contents

Printing is everywhere — from the label on your morning juice bottle to the packaging of your favorite skincare brand. It plays a crucial role in how products are presented, how they feel, and how they communicate with consumers.

At the core of many of these everyday visuals is flexographic printing — a modern, efficient technology widely adopted across various industries. When combined with ultraviolet (UV) curing technology, this process becomes even more powerful, offering greater production efficiency and outstanding print quality.

In this article, we’ll explore what the flexographic printing process entails and how UV curing elevates its capabilities in today’s fast-paced, quality-driven market.

What Is Flexographic Printing

Flexographic printing, often called flexo, is a popular method for printing labels, packaging, and other everyday materials. It works with a wide range of surfaces – such as paper, plastic film, foil, and cardboard. It is valued for its speed, consistency, and cost-efficiency.

What makes flexo unique is its use of soft photopolymer plates. These plates are wrapped around cylinders, and as the material passes through the machine, a roller called an anilox evenly spreads the ink. This helps create smooth, consistent color even when printing large volumes.

Unlike traditional printing methods that only work on flat surfaces, flexo can handle curved and uneven textures thanks to its flexible plates. This versatility makes it ideal for printing on items like snack wrappers, bottle labels, and corrugated boxes.

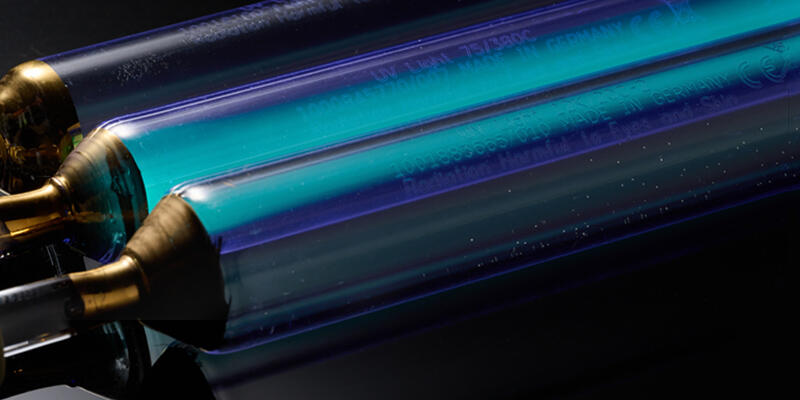

Many modern flexo systems now integrate UV curing technology, which uses ultraviolet light to instantly harden the ink—upgrading the process with cleaner, more durable results. We’ll explore this in more detail later in the article.

How the Flexographic Printing Process Works

The flexographic printing process typically involves five key stages:

Design & Plate Making

Digital artwork is transferred onto flexible photopolymer printing plates using laser engraving or UV exposure. These plates feature raised image areas that will later receive ink during the printing stage.Mounting Plates & Press Setup

The prepared plates are mounted onto plate cylinders, and the anilox rollers, which control ink volume, are installed. The press is calibrated for precise registration, tension control, and proper alignment of the substrate.Printing

Ink is transferred from the reservoir to the anilox roller, then to the plate, and finally onto the substrate. The flexible plate applies the ink in a continuous, high-speed motion, making flexographic printing ideal for roll-to-roll production and large print volumes.Drying & Curing

Depending on the type of ink, drying or curing follows the printing stage. Water-based and solvent-based inks are dried using hot air, while UV inks are instantly cured under UV lamps. This instant curing allows for smudge-free, durable prints that are immediately ready for handling.Post-Processing & Finishing

After printing, the rolls may undergo cutting, slitting, lamination, varnishing, or rewinding. These finishing steps are crucial for enhancing the product’s durability, aesthetic appeal, and functional performance—such as adding protective coatings or preparing substrates for automated application, followed by inspection and packaging to ensure consistent output before shipment.

UV Curing Benefits in Flexographic Printing

UV curing is increasingly favored in flexographic printing for its significant advantages over conventional drying methods:

Faster Processing & Greater Efficiency

Unlike traditional drying systems that rely on heat or solvent evaporation, UV curing initiates a rapid photochemical reaction that solidifies the ink in seconds. This dramatically increases production speed, especially in high-volume operations.Vivid Colors & Durable Finishes

UV-cured prints produce sharp, vibrant colors, making them ideal for high-resolution graphics and visually driven packaging. In addition, the cured surface offers excellent resistance to scratching, heat, and chemicals, which is particularly beneficial in industries like food, beverage, and cosmetics.Broad Material Compatibility

Because UV curing does not rely on ink absorption or evaporation, it can be used on non-absorbent substrates such as metal, plastic, or foil. This makes it highly versatile for modern packaging needs.Improved Environmental Performance

UV curing significantly reduces the release of volatile organic compounds (VOCs), as it eliminates the need for solvent-based inks. Moreover, modern LED-UV curing systems consume less energy and offer longer operational life, contributing to more sustainable production.

Common Flexo Applications Enhanced by UV Curing

UV curing is especially valuable in flexographic printing applications that demand durability, high visual quality, and compatibility with non-absorbent materials. Its benefits are most evident in the following use cases:

Labels & Stickers

Commonly printed on substrates like plastic film (PE, PP, PET), coated paper, and metallic stock, labels require sharp, smudge-free graphics that withstand moisture and friction. UV curing delivers instant drying and vibrant colors, helping brands maintain a strong shelf presence.Flexible Packaging

In sectors like food and beverages, flexible packaging must resist moisture, temperature changes, and repeated handling. UV-cured inks offer the robust performance needed to keep packaging intact and legible throughout the product lifecycle.Cartons

In carton printing, UV curing is not only used for ink but also widely applied in post-print coatings. UV-cured varnishes and finishes, such as gloss, matte, or soft-touch, enhance the visual impact and add surface protection. This is particularly important in high-end packaging for cosmetics, specialty foods, or luxury products where appearance and durability go hand in hand.

UV Curing: The Ideal Partner for Flexographic Printing

Flexographic printing has established itself as a leading printing technology — and UV curing is the key to unlocking its full potential. By delivering higher efficiency, broader material compatibility, and long-lasting print finish, UV curing elevates flexo to a new standard of excellence.

At UV Light, we provide cutting-edge systems and hands-on support to help flexo printers boost productivity, reduce waste, and stay ahead in a competitive market. Contact us to learn how we can help optimize your workflow and sustainability goals.

About the Author : Follow us on LinkedIn.