- Home

- Knowledge Center

- Revolutionizing Labs: UV Curing Applications and Advantages

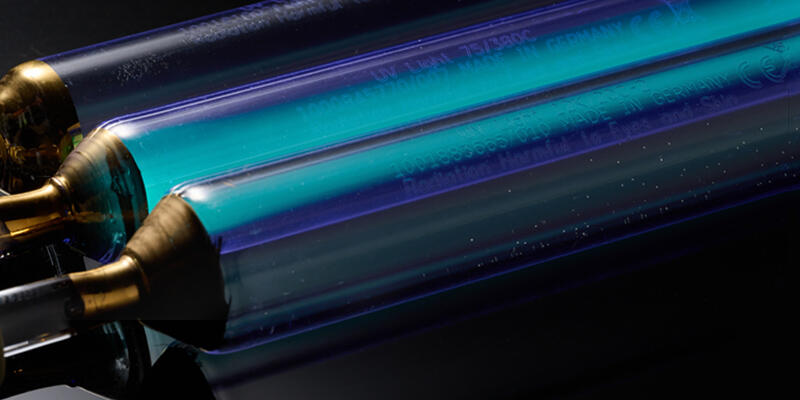

Revolutionizing Labs: UV Curing Applications and Advantages

Contents

Laboratories are evolving, and so are their methods. With the rise of UV curing technology, researchers can now overcome the limitations of traditional curing techniques, enabling faster prototyping and more controlled experimental outcomes in critical industries like semiconductors and medical devices.

In this article, we’ll explore how UV curing applications are transforming laboratory workflows, highlight the key advantages over traditional methods, and examine how this technology is used in cutting-edge experimental settings.

What is UV Curing? Why It Matters in the Lab

UV curing is an advanced technique that uses ultraviolet (UV) light to rapidly harden materials that contain liquid resin, such as inks, coatings, and adhesives. When exposed to UV light, these materials undergo a photochemical reaction that causes them to solidify within seconds.

This technology is widely adopted across industries such as printing, industrial coatings, electronics, UV adhesives, and 3D printing. In recent years, it has also gained popularity in laboratory environments due to its ability to deliver faster, cleaner, and more controllable curing. By enabling more efficient workflows and offering greater operational flexibility, UV curing presents clear advantages over conventional techniques, especially for modern research and rapid prototyping.

In the next section, we will explore the key advantages of UV curing in laboratory applications.

UV Curing vs. Traditional Methods: 5 Reasons Labs Are Making the Switch

UV curing stands out in modern laboratory environments for several compelling reasons:

Fast Curing Speed

Traditional curing methods often require minutes or even hours to complete, which can significantly slow down experimental progress. In contrast, the speed of UV curing supports workflows that demand rapid turnaround.

This advantage is especially beneficial for laboratories engaged in time-sensitive work. For example, in semiconductor R&D or microfluidics, where multiple curing steps must be repeated quickly with minimal downtime, fast curing enables more efficient processing and higher productivity. It also enhances experimental agility in research settings that rely on trial-and-error adjustments, such as early-stage material development or device assembly.Accuracy & Controllability

Accuracy is crucial in laboratory experiments to ensure reliable and reproducible results. UV curing provides excellent controllability, as it can be precisely activated or halted, while its rapid reaction reduces exposure to external variables. This makes it especially suitable for multi-step procedures or delicate assembly tasks where timing and consistency are critical.

By comparison, thermal curing often results in uneven heat distribution, which can lead to material deformation or dimensional changes. Solvent evaporation curing is even more difficult to manage, as outcomes are affected by uncontrollable factors like airflow, humidity, and temperature. These inconsistencies can cause bubbles, shrinkage, or uneven film thickness, all of which undermine experimental precision.Perfect for Heat-sensitive Materials

Unlike thermal curing, which involves high temperatures that may damage heat-sensitive materials such as plastics or electronics, UV curing operates at or near room temperature. This makes it ideal for delicate substrates like biological samples, polymers, and optical components, as it minimizes thermal stress and the risk of material degradation.Operation Safety

Safety is a fundamental concern in laboratory environments. Thermal curing involves high temperatures, increasing the risk of burns and potential fire hazards. Solvent evaporation, on the other hand, emits flammable and toxic vapors, which may compromise air quality and pose health risks to laboratory personnel.

UV curing significantly reduces these risks. While it still requires protective measures such as UV shielding and safety eyewear, the process is solvent-free, emits minimal volatile organic compounds (VOCs), and operates at low temperatures. These features make it a cleaner, safer choice for enclosed and frequently used laboratory spaces.Environmentally Friendly

Solvent-based curing methods are under growing scrutiny due to their high VOC emissions, which contribute to environmental pollution and increasing regulatory pressure. Thermal curing, while solvent-free, is energy-intensive and adds to the laboratory’s carbon footprint.

In contrast, UV curing consumes less energy and generates minimal VOC emissions, offering a cleaner, more sustainable alternative. Its lower environmental impact makes it well-suited for labs aiming to align with green practices and meet evolving sustainability goals.

Essential UV Curing Applications in the Lab

UV curing is particularly valuable in laboratory settings that demand precision, reliability, and material compatibility. Below are some key applications across specialized industries:

Electronics & Semiconductor R&D

UV curing is widely applied in microelectronic encapsulation, die attach and chip bonding, precise dispensing of conductive adhesives, and the use of UV-curable photoresists for lithography and rapid prototyping. Its ability to cure at room temperature minimizes thermal stress on sensitive components such as semiconductor chips. In addition, the high level of control over curing area and exposure time makes it ideal for applications requiring micron-level precision.Optics & Precision Instrumentation

In optical assembly processes, such as sensor and lens integration, fiber optic splicing, and encapsulation, UV curing plays a vital role. Light-curable adhesives and coatings, including transparent and anti-reflective formulations, help preserve optical clarity and structural integrity. The low-heat nature of UV curing prevents warping of delicate components, while its high positional accuracy supports precise alignment and consistent optical performance.Biotechnology & Medical Device Labs

Applications such as microfluidic chip bonding, diagnostic device assembly, and sealing of disposable medical components benefit greatly from UV curing solutions. The rapid, low-temperature process is particularly suited for heat-sensitive and biologically active materials, helping maintain sterility and structural integrity while ensuring precise, reliable results.Materials Science & Coating Research

Materials research labs frequently use UV curing in the development of light-curable polymers, functional coatings, and smart materials. These include anti-corrosion layers, hydrophobic surfaces, and stimuli-responsive films designed for advanced applications. The light-triggered curing process allows precise control of reaction kinetics and supports selective or patterned curing, making it especially useful for prototyping and testing new surface functionalities in mechanical, optical, or chemical experiments.

Enhance Your Lab Performance with UV Curing Technology

Looking to elevate your experimental workflow? UV curing has become an essential technology in modern laboratories, enhancing efficiency, precision, and safety. It’s more than just a technical upgrade—it’s a future-proof investment that supports better results, promotes staff well-being, and aligns with corporate sustainability goals.

At UV Light, we offer lab-specific UV curing systems engineered to meet the diverse demands of research environments. Whether you're working in electronics, biotechnology, optics, or materials science, our systems help researchers, lab operators, and quality testers achieve faster, more reliable outcomes with minimal variables.

Contact us to discover how our solutions can streamline your workflow and support your sustainability initiatives.

About the Author : Follow us on LinkedIn.