- Home

- Knowledge Center

- UV curing technology

UV curing technology

Contents

UV curing technology is essential in everyday life, from food and clothing to transportation and entertainment. Let’s explore what makes UV so important.

1. What is UV?

UV, short for Ultraviolet, is electromagnetic radiation with wavelengths between 200–400 nm, categorized into:

1) UV-A (320–400 nm, 90% market share)

2) UV-B (280–320 nm)

3) UV-C (200–280 nm)

UV LEDs, especially at wavelengths like 365 nm, 385 nm, 395 nm, and 405 nm, are gaining popularity due to their energy efficiency and versatility.

UV curing is a photochemical process that hardens UV-curable materials with light, without solvent evaporation. It’s eco-friendly, low-temperature, and precise, making it ideal for various applications.

2. Why use UV curing?

- Reduces energy consumption

- Environmentally friendly (no solvent evaporation)

- Shortens production time and boosts efficiency

- Saves space and lowers factory setup cost

- Enhances product quality and yield

3. How to select the appropriate UV curing system?

UV curing needs vary by product and process. To select the right system:

- Understand the product's characteristics and select suitable UV materials (e.g., inks).

- Determine the optimal curing wavelength for the materials.

- Design a UV curing system tailored to the material's needs.

With 40+ years of expertise, UV Light Enterprises offers UV-LED and hot-air IR curing solutions for diverse industries. Contact us for more details. Contact us for more details.。

4. Features of UV light sources

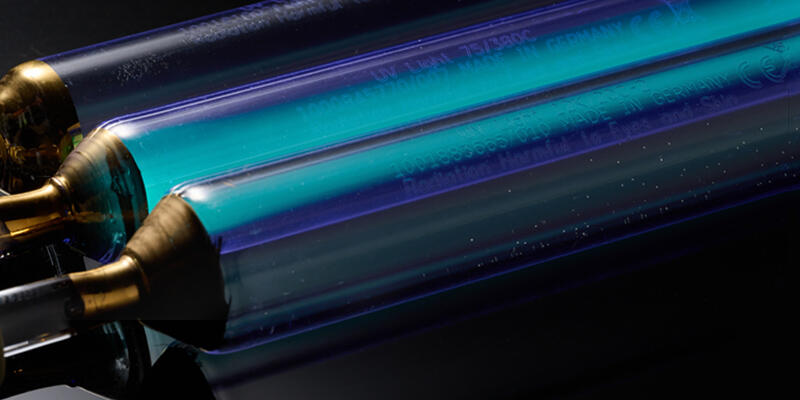

UV lamps work by emitting radiation through ionic discharge in quartz tubes. Key considerations include:

- UV Intensity: 80–120 W/cm.

- Sufficient power ensures complete curing and prevents defects.

- Higher power improves penetration but needs effective heat management.

For detailed solutions or inquiries, feel free to contact us.

About the Author : Follow us on LinkedIn.