- Home

- Knowledge Center

- How Does UV Curing Work? The Chemical Reactions Behind It

How Does UV Curing Work? The Chemical Reactions Behind It

Contents

From food packaging labels to coatings on wrappers and screens, UV curing quietly supports many products we use every day. It’s used to cure printed surfaces, bond materials, seal adhesives, and add protective layers—all with just a flash of light.

In the next section, we’ll take a closer look at how the UV curing process works and what makes it so fast and effective.

How Does UV Curing Work?

UV curing is a process that uses ultraviolet (UV) light to make certain liquids harden almost instantly. These liquids – like special inks, coatings, adhesives, or resins – contain ingredients that react when exposed to UV light. As soon as the light hits them, a chemical change starts inside the liquid, turning it into a solid within seconds. There’s no need for heat or drying; just light.

More specifically, UV curing relies on a photochemical reaction. The liquid is specially formulated with compounds called photoinitiators. When UV light shines on the material, these photoinitiators absorb the energy and release highly reactive particles, such as free radicals or cations. These particles trigger a chain reaction called polymerization, where small building-block molecules (monomers) rapidly link together to form large, solid structures (polymers). This reaction is what turns the liquid into a tough, durable layer—quickly and efficiently.

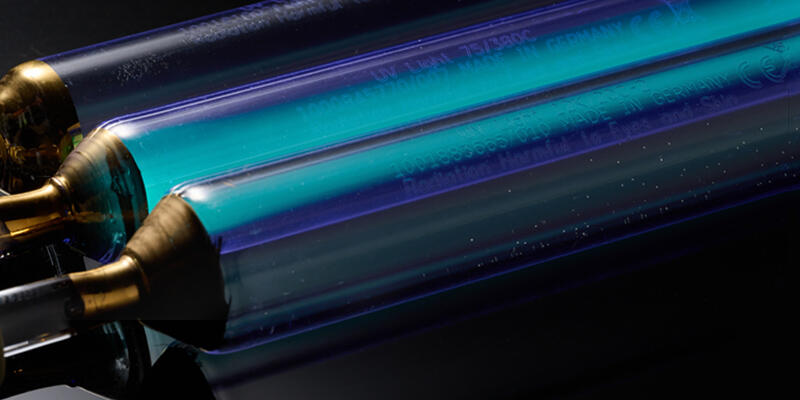

The Role of UV Light in Curing

In UV curing, ultraviolet (UV) light serves as the energy source that initiates the chemical reaction. However, not all UV light is the same—different wavelengths carry different levels of energy and penetrate materials to varying depths. For optimal results, the UV wavelength must be matched with the material’s sensitivity and the desired curing depth.

UVA (320–400 nm): Deep Penetration, Wide Use

UVA light has the longest wavelength and the deepest penetration among the three UV ranges. While it carries less energy than UVB or UVC, this lower energy makes it gentler on materials—minimizing the risk of surface overheating, yellowing, or warping. At the same time, its longer wavelength allows it to reach deeper layers, making it well-suited for curing thicker coatings, adhesives, or transparent materials. Thanks to this balance of deep penetration and lower risk of damage, UVA is the most widely used wavelength in UV curing—especially in printing applications like clear varnishes on labels, protective coatings on flexible packaging, and bonding laminated layers in films.UVB (280–320 nm): Controlled Curing for Surface Layers

UVB light falls in the middle range of the UV spectrum, offering more energy than UVA but less penetration. This makes it well-suited for curing surface-level layers where deeper reach isn’t needed. Its limited penetration gives better control over where the curing occurs—useful for preserving sharp print details or avoiding unintended effects in underlying layers. UVB is commonly used for curing inks, top coatings, and printed finishes that benefit from fast, targeted surface hardening.UVC (200–280 nm): High Energy for Specialized Curing

UVC light has the shortest wavelength and the highest energy in the UV spectrum. While its intensity can lead to material degradation, warping, or yellowing, it also enables very fast curing reactions. Because of this, UVC is mainly used in specialized applications where high reactivity is needed and the materials are designed to tolerate its energy. It’s often combined with other UV wavelengths to enhance curing performance in advanced systems.

What Are the Ingredients for UV Curing?

Although UV curing seems to happen quickly, it relies on a carefully formulated mixture beneath the light. A typical UV-curable material—whether it’s ink, adhesive, resin, or coating—contains three essential components, each with a distinct role in how the material spreads, cures, and performs.

Photoinitiator (1%–10%)

Photoinitiators act like the “on-switch” in UV curing—they’re light-sensitive ingredients that absorb UV energy and become highly reactive. Once activated, they generate free radicals or cations, which trigger the chemical reaction that hardens the liquid material into a solid form.Oligomer (50%–80%)

Oligomers are the pre-made building blocks of the cured material. These short-chain polymers form the core structure. Once curing begins, oligomers link together to create a strong, durable surface. They play a major role in defining the final product’s hardness, flexibility, and chemical resistance.Reactive Diluent / Monomer (20%-40%)

Monomers are small, fast-moving molecules that serve two critical roles: they make the formula less sticky and easier to apply, and they are also the main ingredient that reacts with the photoinitiator. Once triggered, monomers bond with other monomers and oligomers, effectively bridging the structure together to form a tightly connected polymer network. The ratio of monomer to oligomer controls how fluid the mixture is before curing and how strong or flexible the final product becomes.

UV Curing Processes

UV curing transforms liquid into solid through a rapid chain reaction triggered by UV light. This reaction typically follows one of two chemical pathways: Free Radical Polymerization (FRP) or Cationic Polymerization (CP). While both lead to crosslinked solid structures, FRP links molecules directly, while CP starts by opening ring-shaped molecules with strong acid.

Each mechanism follows its own sequence of steps, from light activation to final solid structure. Let’s look at how each process works.

Free Radical Polymerization (FRP)

Common in printing, coatings, and adhesives.UV Activation

The photoinitiator absorbs UV light and splits to form free radicals – reactive particles that are essentially “woken up” by the light. This marks the starting point of the reaction.Chain Initiation

A free radical attacks a carbon-carbon double bond (C=C) in a monomer, opening it up and creating a new reactive site, like unzipping the first link in a chain.Propagation

This reactive site pulls in more monomers or oligomers, allowing the polymer chain to grow longer and longer, rapidly building the structure.Crosslinking

As multiple chains form, they begin to interconnect, creating a strong, mesh-like network that gives the material durability and resistance.Termination

The reaction ends when two radicals combine and cancel each other out, or when no more reactive sites are available—much like reaching the last puzzle piece.

Cationic Polymerization (CP)

Used in epoxy systems and applications requiring strong adhesion and chemical resistance, such as electronic coatings, optical film bonding, and specialty adhesives for glass or metal, cationic polymerization plays a key role in high-performance curing. Many materials used in this process—especially epoxy resins—have ring-shaped molecular structures that must first be opened before the chain reaction can begin.UV Activation

The photoinitiator absorbs UV light—typically in the UVB to UVA range (250–320 nm)—and generates a strong acid (H⁺), which acts as the initiator for the ring-opening reaction.Molecular Ring Opening

This acid attacks closed molecular structures like epoxy rings, forcing them open and forming reactive cations. This acid essentially “unlocks” the molecule, making it ready to bond.Propagation

These reactive sites continue reacting with nearby monomers and oligomers, growing into long polymer chains and expanding the structure.Crosslinking

As in FRP, these chains link together to form a solid, crosslinked material with enhanced toughness and resistance.Dark Curing

Unlike FRP, cationic polymerization is less sensitive to oxygen and can continue even after UV exposure ends. This “dark curing” means the reaction can proceed in shaded or partially hidden areas—an advantage for curing complex shapes, thick layers, or areas where light penetration is limited. As long as the reactive cations remain active, the material continues to harden even without ongoing UV light.

Conclusion

UV curing may look simple on the surface, but the process involves precise chemistry, material compatibility, and carefully controlled light exposure. Understanding how all these elements work together is key to achieving reliable results. That’s where UV Light comes in—helping you navigate the complexity and choose the right system for your production needs. Contact us today to find the UV curing solution that fits your process.

About the Author : Follow us on LinkedIn.