Products

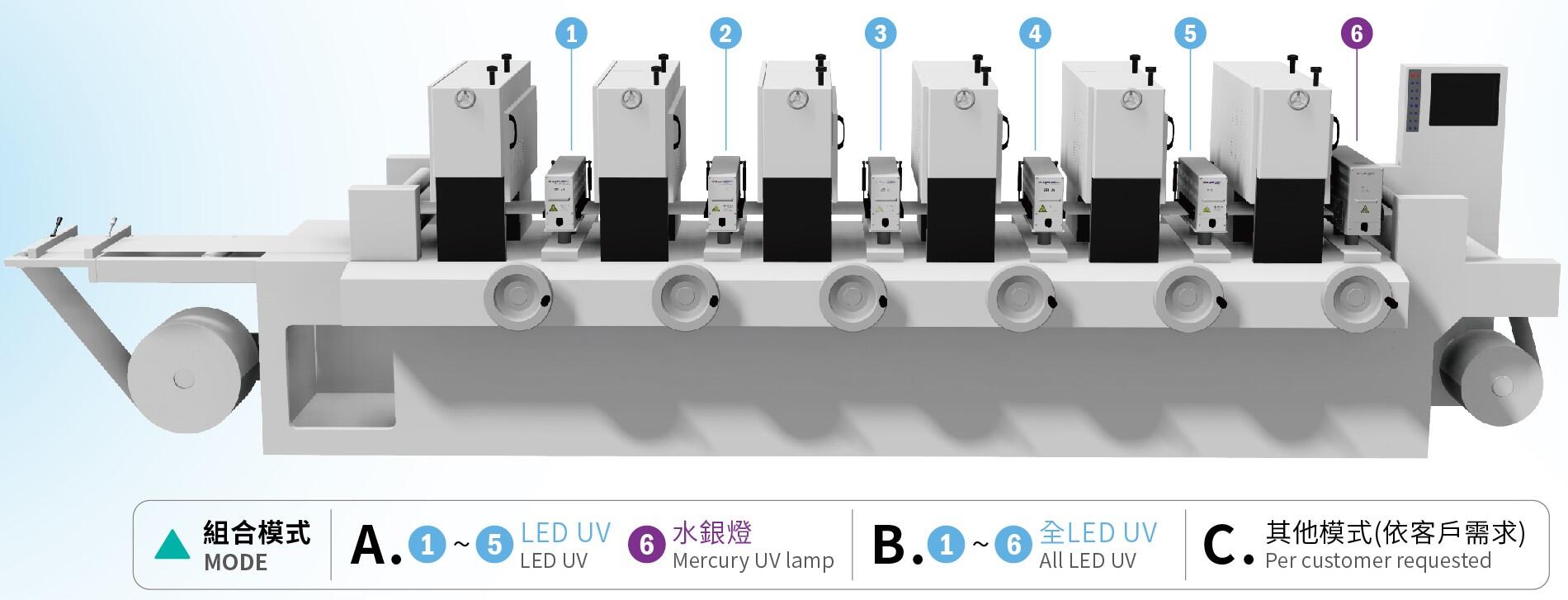

LED UV Curing Systems

LED UV technology is the solution to energy efficiency. Compared to conventional UV drying systems, LED UV offers a remarkable solution, potentially reducing energy consumption by up to 80%. This decrease in energy usage translates to not only cost savings but also notable environmental advantages. Moreover, it operates at much lower temperatures, ensuring that heat-sensitive materials are processed without damage. LED UV technology and its industrial applications (reference webpage).

LED UV has diverse applications in curing coatings, adhesives, and inks. It's particularly esteemed in screen printing, flexo, offset, label printing, and digital printing. In addition to our standard series, custom curing widths and working distances are available upon request. The LED UV system is now taking over and applied to almost all the fields that conventional UV used to do, with more solid and compatible use.

Features

- High UV Intensity Output: LED UV systems emit intense UV that effectively penetrates deep into ink layers, ensuring rapid and thorough curing.

- Improved Efficiency: No need for preheating or waiting time, instant operation, and shortened preparation time.

- Material Compatibility: Suitable for a wide range of printing materials, with low heat generation during the curing process, making it compatible with heat-sensitive materials.

- Energy Savings: LED UV curing is highly energy-efficient, leading to a reduction of approximately 80% in energy consumption compared to traditional methods.

- Eco-Friendly: UV LED is eco-friendly as it doesn't produce ozone and is entirely mercury-free.

- Long Lifespan: With an average LED life expectancy of over 25,000 hours

Specification

Water-cooled LED

- Intensity: 8-20W/ cm²

- Curing Width: 300mm-1100mm

- Distance: 20mm-100mm

- Wavelength: 365-405nm

- Cooling Method: Water

Air-cooled LED

- Intensity: 8-16W/ cm²

- Curing Width: 200mm-400mm

- Distance: 10mm-40mm

- Wavelength: 365-405nm

- Cooling Method: Air

UV Light is committed to assisting you in adopting this leading technology. Experience energy savings, enhanced efficiency, and eco-friendliness with UV LED Curing. Do not hesitate to reach out to us for further details and technical discussion.

Environmental Protection ・Eco-friendly

UV Curing Systems

A UV curing system, short for ultraviolet curing system, is a technology used for quickly drying or curing inks, coatings, adhesives, and other materials by using ultraviolet (UV) light. This system involves the use of UV light to initiate a chemical reaction in the material, causing it to harden or dry almost instantly.

The UV curing systems manufactured by UV Light are widely used in consumer goods, including printed packaging, glossing on packaging boxes, self-adhesive labels, electronics, wood products, spray coatings, and more. These systems offer enhanced gloss, abrasion resistance, solvent resistance, and improvements in printing efficiency and quality. Additionally, real time monitoring ensures that the curing process is consistently optimized, providing precise control and data analysis for enhanced product quality.

Features

- High power output up to 600W/INCH.

- Curing width available from 150MM to 1500MM.

- Indirect reflection lowers the temperature of the material more than 55%.

- UV power auto adjustment to suit the speed of the web press.

- Available for lower temperature design of air/water curing type.

- Designed for curing heat-sensitive optical films.

As one of the leading UV manufacturers in Asia, UV Light also provides real time monitoring solutions for UV curing.

Optional:

- Built-in efficient German-made dichroic reflectors.

- UV Energy Real-time Analyzer System.

- Real-time UV energy monitoring, and data management.

- Fine tuning for different quality segments.

- Curing quality data could be accessed easily.

- Providing curing data for in-depth analysis of product quality.

UV Light has been devoted to designing and manufacturing UV systems for different fields since 1983. We are ISO 9001:2015 certified. UV Light is your trusted partner in UV curing technology, quality, and excellence. For further details and inquiries, please do not hesitate to contact us.

IR and JET-AIR Systems

Infrared (IR) heating is a clean and highly efficient heating method. It's widely used in numerous industrial equipment where rapid heating, pollution-free operation, and energy efficiency are paramount. Depending on the temperature of the heating element, infrared emitters deliver radiation at varying wavelengths. Hence, selecting the appropriate emitter for your product is vital. UV Light's IR and JET-AIR Drying Systems are an excellent choice for such requirements.

Our product serves a diverse range of printing needs. These specialized curing systems can satisfy the needs for clear and sharp printing of fine characters and the leveling with high gloss of varnish printing. The emitted radiation from our lamps surpasses the efficiency of traditional heating methods like convection or conduction heating.

Features

- Efficient Heat Exchange System: Our system boasts a hyper-efficient heat exchange mechanism, optimizing energy usage while providing consistent results.

- Pneumatic Cross-Over Infeed Section: The pneumatic cross-over section can be folded down for easier cleaning of the screen.

- Special Airflow Design: Designed with precision, our system prevents thin paper from fluttering during printing, granting accuracy.

- Automatic Conveyor Correction: To prevent belt drifting, we have implemented an automatic correction system in the conveyor, guaranteeing smooth and precise movement.

- Negative Pressure Design: Our system creates negative pressure, expelling solvents more efficiently while promoting better solid curing.

- Temperature Control: You can stepless adjust the temperature from room level to 90 degrees Celsius, providing flexibility in your printing processes.

- UV and IR Lamp Compatibility: The UV and IR lamp can be additional for drying various inks.

IR and JET-AIR Systems are applicable with Sakurai screen printing press, SPS screen printing press, and so on. These systems can be custom-designed, manufactured, and installed to meet specific customer requirements for various equipment and machinery.

UV Light offers solutions for not only UV drying but also thermal and IR drying. Please do not hesitate to contact us for further details or technical support.

UV Conveyor

UV Curing Conveyor

UV Light can be matched with customer process requirements to produce UV conveyor equipment transmission devices. Great partners with Sakurai screen printing press, SPS screen printing press, and so on.

FEATURES:

- This special UV curing system can satisfy the needs for clear and sharp printing of fine characters and the leveling with high gloss of varnish printing.

- The UV and IR lamps can be additional for drying various inks.

- Special airflow design, thin paper won’t flutter.

- Zero speed sensor is equipped to prevent the fire issue if the conveyor slips.

- An automatic correction system of the conveyor has been designed to prevent the belt from drifting.

- Pneumatic Infeed section could be folded down for easier cleaning of the screen.

- The hood of every section is lifted automatically by Pneumatic cylinders, which make the inspection and maintenance easier.

- Slide in/out UV cassette for easier cleaning and maintenance.

- The design of jet-air and negative pressure leads the solvent easier to the outdoors, as well as the better solid curing.

- The temperature could be adjusted stepless from room temperature to 90°C/150°C.

SPECIFICATION:

(Special requirements from customer can be produced.)

| Model | GYJ900 | GYJ1150 | GYJ1450 |

|---|---|---|---|

| Belt Width (mm) | 850 | 1100 | 1400 |

| Total Width (mm) | 1500 | 1750 | 2050 |

| Conveyor Belt Speed | 5-60 m/min | ||

| Max Temperature | 90~150℃ | ||

Do not hesitate to reach out to us for further details and technical discussion.

Components

It is extremely important to use genuine spares for reliability, longevity and peace of mind.

Wherever you are, we can ensure you have all the parts and support you need to keep the UV system operating to its full potential. We produce spare parts for all our gear. From dryer elements and UV lamps to dichroic reflectors via mounting components. UV energy meter that can measure energy, power, temperature, time at the same time. We ensure to have all kinds of spare parts in case a client needs them.

If you are an existing UV Light equipment customer and have service inquiries or spare parts inquiries, or if you have consumables, replacements, or system additional services, please contact us.