- Home

- Application

- Printing

- Label

Label

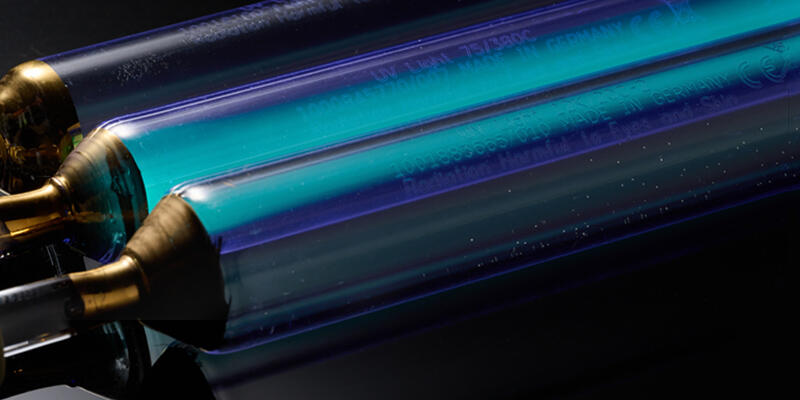

The application of UV (Ultraviolet) in label printing machines is quite extensive in the label and packaging industry. UV printing technology brings significant advantages to label printing. Here are the advantages of using UV in label printing machines:

- High-quality printing: UV printing technology provides outstanding print quality, presenting more vibrant, clear colors, and details. This is particularly crucial for labels requiring high visual appeal, such as food, beverage, and cosmetic labels.

- Rapid curing and production efficiency: UV light curing enables inks to dry and harden instantly, thus increasing production speed. This is highly advantageous for large-scale production and short delivery timelines.

- Printing on various materials: UV printing is suitable for various label materials, including films, paper, metals, etc. This flexibility allows manufacturers to meet the demands of different industries and applications.

- Special effects and selective coating: UV printing allows for the addition of special effects like gloss, matte, three-dimensional effects, etc. It also enables selective coating, applying UV coatings only in specific areas as needed.

- Wear and weather resistance: Prints produced through UV printing typically exhibit superior wear and weather resistance, making labels more durable during transportation and usage.

- Environmentally friendly: UV printing processes do not require the use of volatile organic compounds, reducing environmental impact and aligning with eco-friendly standards.

The application of UV in label printing machines is typically reflected in improved print quality, production efficiency, application flexibility, and environmental friendliness. This makes UV technology a popular choice in the label and packaging industry.