- Home

- Knowledge Center

- Elaborating on LED UV Curing Equipment-1

Elaborating on LED UV Curing Equipment-1

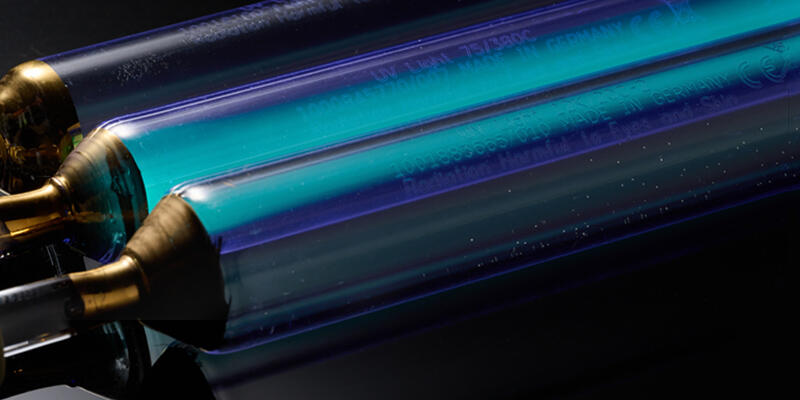

UV Light in LED UV curing equipment. Below is an introduction to the comparison between LED UV curing equipment and traditional mercury lamp UV curing equipment. UV curing equipment is well-known and widely used in industrial production, and LED UV curing equipment has also undergone continuous research and development for improvement.

The production process dominated by mercury lamp irradiation has been adopted for a long time. However, due to the expensive equipment prices, high maintenance costs, rapid decay of UV light intensity, high surface temperature of irradiated components, large size, expensive consumables, mercury pollution, and other defects, the industry has been committed to improvement. However, due to the limitations of the original solid-state technology, it has been difficult to break through. The advent of LED UV curing equipment has brought revolutionary changes to the UV curing industry.

LED UV curing equipment can directly convert electrical energy into UV light, emitting a single wavelength of ultraviolet light. The light energy is highly concentrated in specific UV wavelength bands. Currently, in the market, the maturely applied wavelengths are 365nm, 385nm, and 395nm. In contrast, the emission spectrum of traditional UV mercury lamps is broad, with only a portion of the spectrum being effectively utilized for curing. Additionally, they have low photoelectric conversion efficiency and high energy consumption.

Traditional mercury lamp UV curing machines can generate infrared radiation and emit a large amount of heat, which can easily damage heat-sensitive substrates. LED UV curing equipment can effectively avoid substrate shrinkage and deformation caused by overheating, and it has a wider range of material adaptability. Moreover, UV LED curing machines used for UV curing typically emit longer-wavelength ultraviolet light, so they do not generate ozone during the curing process, maintaining a good working environment. Compared to traditional mercury lamps, LED UV curing equipment is safer and more environmentally friendly.

About the Author : Follow us on LinkedIn.