- Home

- Application

- Printing

- Sheetfed Offset

Sheetfed Offset

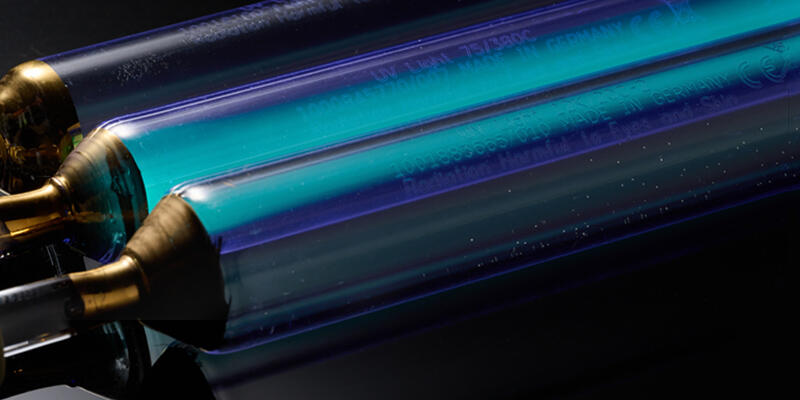

UV CURING SYSTEM FOR OFFSET PRESS

The combination of offset printing machines with LED UV curing systems brings various advantages and has become increasingly popular in the printing industry. Here are some advantages of offset printing machines with LED UV:

Low energy consumption:

LED UV, compared to traditional mercury lamp light sources, can reduce energy consumption. LED light sources are more energy-efficient during operation, and they do not require preheating or cooling when starting and shutting down, further reducing energy waste.Low-temperature curing:

The UV light generated by LED UV systems is cool, without producing heat. This allows printing materials to cure at lower temperatures, which is particularly beneficial for sensitive materials like plastic films or thermal paper.Fast curing for high production efficiency:

LED UV light sources can instantly cure ink or coatings, increasing production speed. This also allows immediate post-processing steps, reducing the overall printing production timeline.Wider material adaptability:

LED UV, paired with light sources of different wavelengths, can adapt to various printing materials, including thermal paper, films, thick paper, providing greater flexibility in printing applications.Environmentally friendly:

LED UV systems do not require the use of harmful substances like mercury, and the UV radiation generated during operation does not produce odor or toxic gases. This aligns with environmental standards and contributes to creating a green printing environment.

The combination of a flexographic printing machine with LED UV brings energy efficiency, broader adaptability to printing materials, increased production efficiency, and environmental advantages, making it a popular technology in the modern printing industry. Companies specializing in light sources have high customization capabilities to plan the most optimized production applications for your needs.