- Home

- Application

- Printing

- Flexo

Flexo

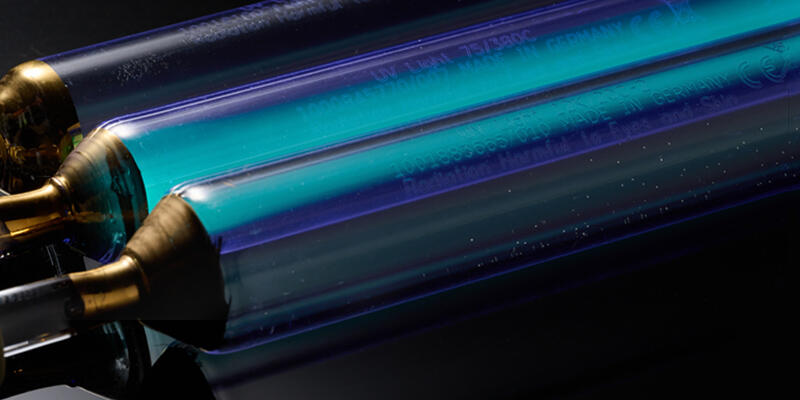

Flexographic printing is commonly used for mass production of packaging materials, labels, paper, etc. When combined with ultraviolet (UV) light-cured inks or coatings, it allows for instant drying and hardening, thereby enhancing printing speed and quality. The advantages of flexographic printing combined with UV Light Enterprise’s UV curing system are as follows:

- Rapid curing and drying: UV curing causes inks or coatings to harden instantly, significantly increasing production speed. This is particularly advantageous for flexographic printing that requires high efficiency and large-scale production.

- Improved print quality: UV curing prevents ink penetration, enhancing print clarity and color vibrancy. This is crucial for applications that demand high-quality printing, such as packaging and labels.

- Versatility in material usage: UV curing can be applied to various materials, including plastic, metal, paper, etc. This versatility allows flexographic printing to be employed in a broader range of applications.

- Environmental friendliness: UV curing eliminates the need for solvents, reducing the emission of volatile organic compounds (VOCs) and thereby minimizing environmental impact. It aligns with environmental standards.

- Wear and chemical resistance: UV-cured inks typically exhibit superior wear and chemical resistance, making printed materials more durable and suitable for challenging environments.